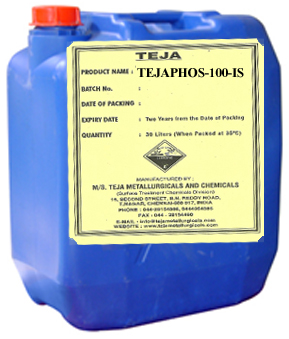

TEJA METALLURGICALS AND CHEMICALS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TEJA METALLURGICALS AND CHEMICALS

Spray Dip Iron Phosphating Chemical

Product description

Tejaphos-100-IS is a Iron Phosphating Chemical for spray application to produce fine smooth thin phosphate coating on Iron and steel surfaces. The metal surface becomes inert, non conductive, rust resistance and do not allow the rust to crisp whenever any rusting occurs due to external damage. The rust is visualised to the same point & spot and does not spread beneath to the point film. It produces smooth crystalline surface and acquire high grip for paint bonding and there by avoid peeling of paint films due to stress or heat.

Tejaphos-100-IS is a low temperature phosphating chemical, it subsequently saves heating cost. The coating produced with Tejaphos-100-IS process is smooth free grained and evenly distributed coating.

Product Specifications

Colour

White Liquid

Odour

Slightly pungent

Foaming Tendency

Nil

Reliability

Good

Handling

Avoid skin contact

Solubility

Good

pH

Acidic Range

Toxicity

Acidic

Flash Point

Nil

Pollution Hazard

Treatable

Product Operating Data

Dipping

Spray

Concentration

1.5-2%

1.5 - 2%

Temperature

25-50*C

25 - 50°C

Time

7-10 minutes

1 – 2 minutes

Pressure

14 point

12 – 15 Psi

Product Operating Procedure

Following process sequence is to be followed

Degreasing

Rinsing

Surface Activation

Phosphating

Rinsing

Rinsing

Passivation

D. M. Rinsing

Drying

Product advantages.

1. Forms light amorphous Iron phosphate coatings over iron and steel components.

2. Forms Zinc phosphate coatings on galvanized steel surfaces by converting a part of

the zinc surface into an integral zinc phosphate coating.

3. Forms aluminium phosphate coating on aluminium surfaces. The phosphate coating so

formed will be a good base for subsequent liquid painting and powder coatings.

4. May be used as 3 (or) 5 stage, depending upon type and degree of oils and superficial

impurities.

5. May be used by dip (or) spray process.

6. In spray process the dwell time is 1-3 miniuts.

7. In dip process the duration of dip is 7-10 miniuts

For every 100 liters of bath

Fill the tank with suitable working level at 1.5% – 2% conc.,

Adjust free acid with soda ash.

stir the bath with pump for thorough mixing

Product Application Equipments

Tejaphos- 100-IS tank should be fabricated with 3 to 4 mm thick M.S./S.S.316 plates with continuous convection current hating system.

SafetyMeasures

Tejaphos-100-IS is an acidic liquid material, and while handling proper care should be taken while handling the material. Protect eyes and skin by means of goggles, aprons, gloves, etc. It comes in contact with skin and eyes wash thoroughly with a flush of water and get medical advice. For further Information please refer our Material Handling and Personal safety Data Sheet No.2.

General Information

Corrosion Resistance: Excellent.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.